Industrial Design Engineer

How can we simplify and fasten the production process of the product?

optimization process

Problem

The current production process of the paste takes months to dry out.

Solution

Design a mould implementing a new production technique & a material to enhance the paste structure fitting the requirements.

Permeable mold

3D printed mold

Layers

Coating

Some materials are not strong enough

Slow production process

Decreased strength

Needs a strong biodegradable material

possible production techniques

testing

Production Technique

Substructures

Aplication Technique

Coatings

Additives

Molds

new material

The new material, should be completely biodegradable after 5 years underwater with no residue.

material testing plan

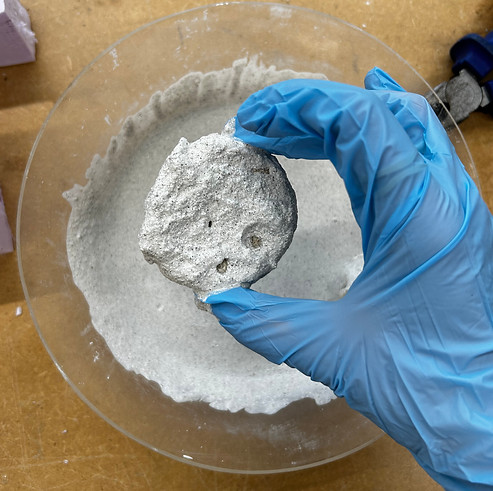

Test 0: Mixing amounts for oyster shell, binding additive and water

Test 1: Different drying methods

Test 2: Different molds

Test 3: Substructure + Application technique

Test 4: Additives

Test 0

Water & Binding

Test 2

Molds

Test 1

Drying method

Test 3

Substructure

Test 5

Additives

Testing methodologies

In order to choose a material & production technique.

Mold shape

Structure

Production

Mycelium is grown into the mould to create the desired shape.

It is then coated with the BESE paste.

Improvements

Mycelium provides a more sturdy structure to the product.

The decrease of BESE paste makes the piece dry faster, enhancing the production time.

The paste provides coating underwater, which has been previously tested, once it degrades the mycelium is a biodegradable material and will not leave harmful residues in the oceans.